TPU-HS

eSUN's TPU-HS maintain excellent strength and printability while offering superior antibacterial, antifungal properties and good flexibility.

TPU-HS

Product Description:

During high-speed printing, eSUN’s TPU maintains high flowability by balancing fluidity and viscosity while considering strength and formability. They demonstrate excellent antibacterial and antifungal effects, with antibacterial rates of up to 99.9% against Escherichia coli and Staphylococcus aureus and a mold resistance level of 0—resistant to mold erosion.

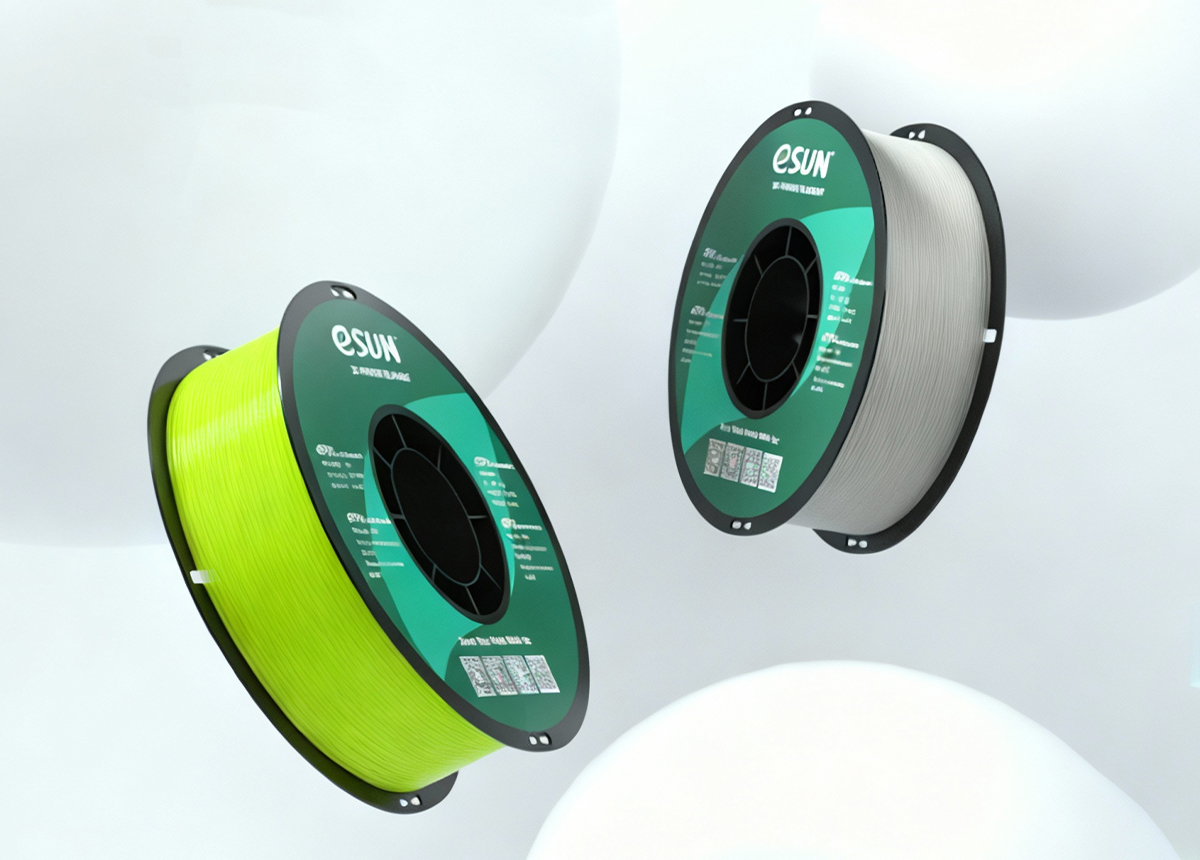

Color: CLEAR, FLUORESCENT YELLOW

Diameter Size: 1.75mm

Net Weight: 1kg/spool

Request a QuoteDescription

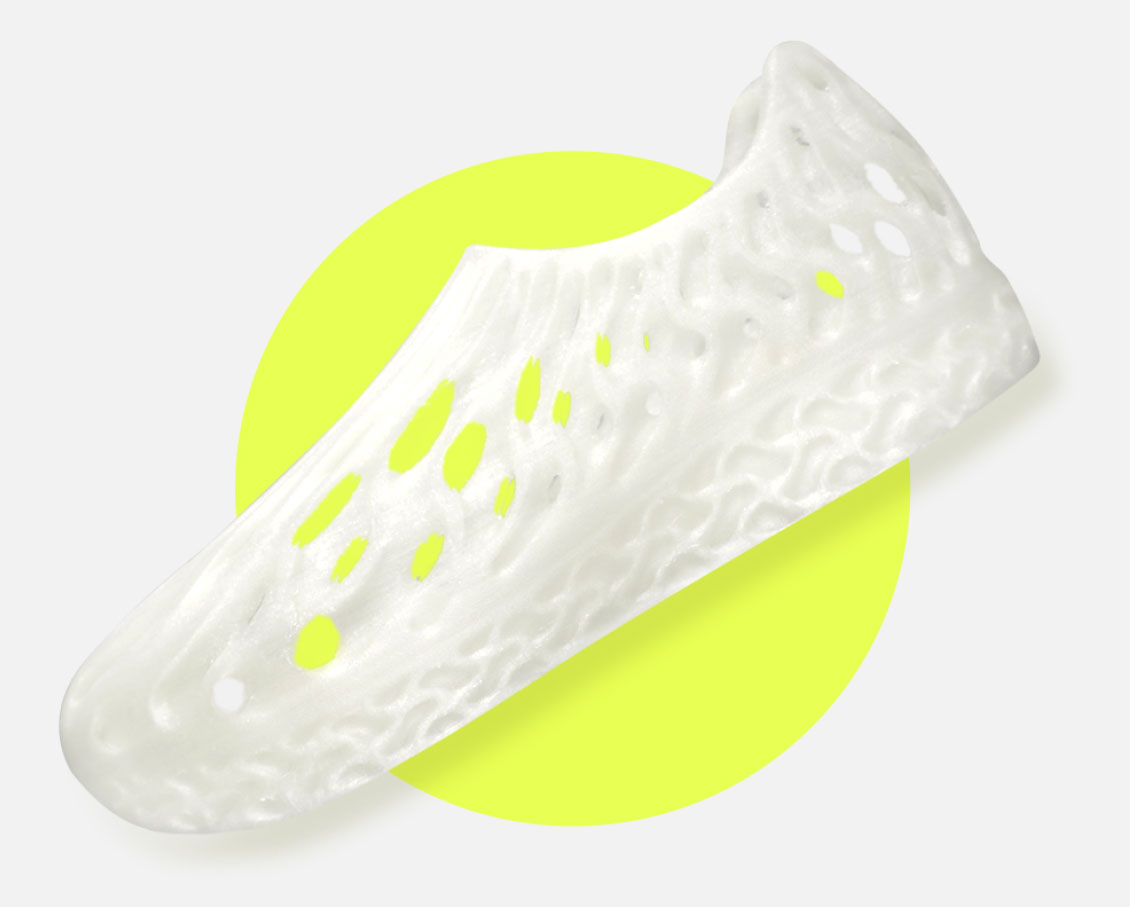

TPU-HS possess good flexibility with a hardness of 95A, making them easy to print and enabling the rapid production of large, complex, and precise prototypes of elastic components. They exhibit outstanding elasticity, ensuring minimal deformation of the printed products. They are durable and long-lasting. With excellent tear resistance, wear resistance, and cut resistance. The materials feature a higher hardness level combined with good resilience, making them suitable for applications such as tires, insoles for footwear, etc.

Features

Antibacterial and mildew proof

Flexible and soft

Strong and sturdy

High elasticity

High toughness

High impact resistance

High-speed printing

Excellent printability

DETAILS

Parameter Information

| Density(g/cm3) | 1.21 |

| Melt Flow Index | 1.2(190℃/2.16kg) |

| Extruder Temperature(℃) | 220-250℃/428-482℉ |

| Bed temperature(℃) | 45-60℃ |

| Fan Speed(%) | 100% |

| Printing Speed(mm/S) | 50-200mm/s |

| Heated Bed | Need |

| Printing Suggestions | Drying at 55℃/>4h, short-range extruder |

Download

eTPU-HS HS Parameters for Bambu Lab & Creality

Notes

1. Try to dry the printing (55℃/>4H) to achieve the best printing effect. It is recommended to use it with the eBOX lite when printing.

2. It is recommended to use a short-range double-wheel deceleration extruder for flexible design. Generally, TPU-95A material is difficult to print with a remote extruder. Try to print at a slower speed with a remote extruder. 20mm/s or under is recommended.

3. The nozzles may have impurities remaining after a long printing time. It is recommended to use in conjunction with the cleaning lines. Replace the nozzles and throats with new ones when necessary.

Leave Message

Leave Message